Magnussonde

Magnussonde – A hermetic flow sensor for medical and industrial applications

One of the most important parameters in patient ventilation is measuring the amount of gas being supplied to the patient by the ventilator with every breath. Even a short failure of the sensor determining this gas flow to the person being treated can lead to suboptimal ventilation. Water droplets accumulating on the sensor element from moist breath due to condensation can affect the measurement accuracy of the sensors used today (e.g. MEMS or differential pressure sensors) and, in the worst case, can even lead to a complete failure of the flow measurement.

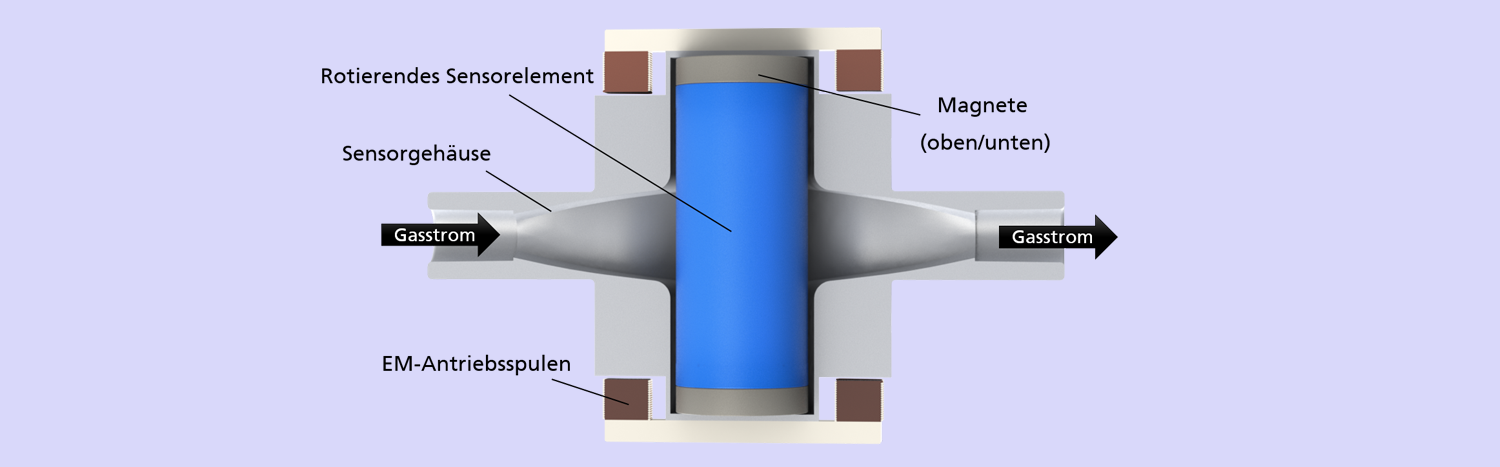

This is where the project Magnussonde of the Mannheim Fraunhofer IPA department »Clinical Health Technologies« comes in. Our aim is to develop a new type of flow sensor that is highly reliable even for the measurement of condensing fluid flows. Further requirements are the use of single-use elements, a low dead space volume and a hermetic design of the sensor. The use of magnetic coupling means that no feedthroughs or windows are required, which also makes the sensor interesting for industrial applications, such as for the measurement of corrosive media.

Magnussonde uses the Magnus effect

The measuring principle of the sensor is based on the Magnus effect, which is generally known from the so-called "banana flank" in football. The Magnus effect is the cause for a rapidly rotating ball being deflected into a circular path transverse to its direction of flight. This deflecting force is greater the faster the ball rotates and the faster it flies through the air. The magnetic probe makes use of this relationship. A small ferromagnetic cylinder is held in suspension and set in rotation by a system of magnetic coils. The force exerted on this suspended body by the gas flow is detected by the specially developed control electronics and converted back into the instantaneous flow. The measurement setup consists of two parts: a sterilisable and encapsulated sensor housing, which can be designed as a single-use component, and an external drive and measurement unit.

Reliable measuring principle thanks to the Magnus effect

One of the multiple advantages of this measuring principle is the fast rotation of the cylinder which prevents condensate from accumulating inside the sensor. Furthermore, the dynamic measuring range of the sensor can be adapted to the respective measuring conditions by varying the cylinder rotation. In principle, the sensor can be used for the measurement of gas as well as liquid fluid flows.

The project Magnussonde was supported by the Vector Foundation and the Fraunhofer internal preliminary research program.

Fraunhofer Institute for Manufacturing Engineering and Automation

Fraunhofer Institute for Manufacturing Engineering and Automation